Desiccant Breathers

FAQ's

A desiccant breather is a device used to prevent moisture and particulate contamination in lubricants and hydraulic fluids by removing humidity and filtering air entering equipment.

Most desiccant breathers change color (e.g., from orange to green or clear to pink) as they become saturated with moisture.

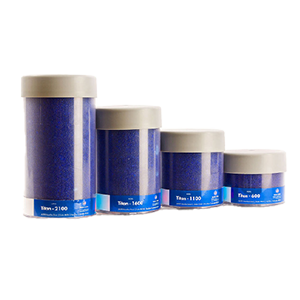

- Standard Desiccant Breathers: Compact, ideal for small reservoirs and light-duty equipment.

- Titan Desiccant Breathers: Larger capacity, designed for heavy-duty applications and long life.

Yes, rebuildable desiccant breathers allow for cost-effective maintenance by replacing only the saturated desiccant and filters.

TitanBlock breathers are specialized for extreme environments with enhanced durability and filtration capabilities.

Adapters ensure proper fitting on equipment and can include specialized features like check valves to improve performance.

Filter carts are portable filtration systems used to remove contaminants from hydraulic and lubricating fluids during transfer or maintenance.

Yes, many filter carts are designed to manage a range of viscosities with adjustable flow rates.

Replace the elements when the pressure gauge indicates a rise, signaling clogging, or as recommended by the manufacturer.

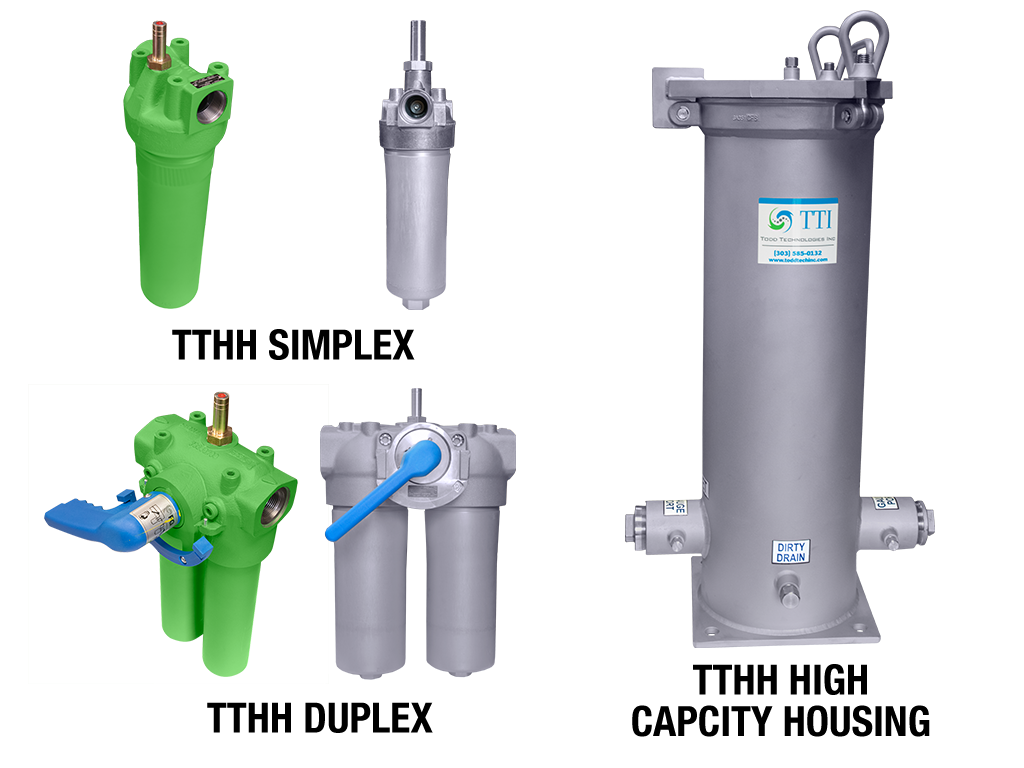

PowerGuard housings are protective enclosures for filtration elements, ensuring efficient operation in demanding industrial applications.

Spin-on elements are replaceable filters designed for quick and easy installation in lubrication and hydraulic systems.